Researchers at the HSZG, TKG Görlitz GmbH and the engineering firm ERTECH are defying the currently difficult conditions to work on future sealing systems for autoclaves.

This news article about the research collaboration between the Institute of Process Engineering, Process Automation and Metrology (IPM), Turbinenkomponenten Görlitz GmbH (TKG) and the engineering firm ERTECH has been sitting in the virtual drawer since the end of February. Since then, the events surrounding the rapid spread of Covid-19 in Germany and around the world have brought many other priorities to the fore. A month later, we are using the time that has passed to not only present the project here, but also to ask the scientists Thomas Gubsch and Torsten Klette (IPM) how the research is going under home office conditions.

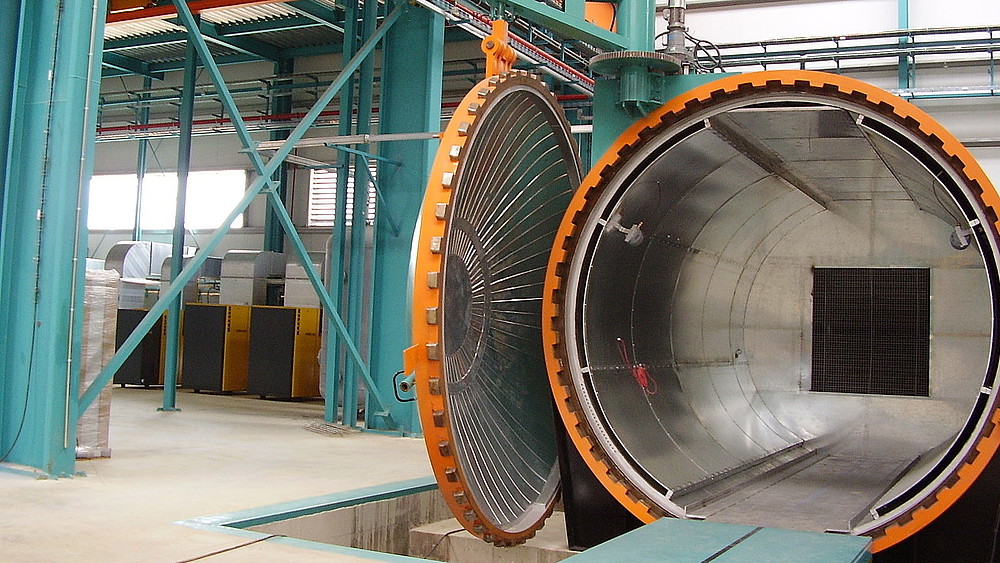

Autoclaves are containers in which high pressure and high temperatures prevail. They are used for a wide variety of purposes: for cooking as a pressure cooker, to sterilize medical devices or to "bake" building materials such as aerated concrete or sand-lime bricks - just like in this project. This application requires large systems of up to 3 m in diameter and 50 m in length, in which pressures of up to 16 bar and temperatures of up to 210 °C prevail for several hours. The autoclave door requires a reliable seal to be able to withstand these pressures permanently. Until now, these huge seals have had to be replaced at great expense after a certain period of use.

This is where TKG's idea comes into play. The aim is to develop a new type of fully automated and low-wear closure system. This would achieve what is so urgently needed for the successful structural change in Upper Lusatia - TKG is transforming itself from an extended workbench into a component developer and manufacturer.

The new development of the door seal is to be made possible, among other things, by a sophisticated measuring system for monitoring the internal condition of the autoclave and the sealing system. And this is precisely one of the core competencies of the IPM at the HSZG. The two engineers Torsten Klette and Thomas Gubsch will contribute this expertise to the "Autoclave" project. They will also be responsible for testing the measurement technology and, last but not least, a reliable safety concept. The development of the sealing geometry and the closure system will be largely implemented by TKG and the engineering firm ERTECH.

The planning and construction of the scaled-down AUTOKLAVEN is already underway, with initial seal tests being carried out and the fully automatic closure system being developed. The coordination rounds with the authorities and the planners from TKG and ERTECH have also begun.

The development of the safety concept based on the values measured inside the autoclave is particularly important. This is because an uncontrolled escape of steam and condensate if the door is opened too early would endanger human health.

It suits the two engineers and their partners in their research that they are currently still in the first project phase, the planning phase. The focus of the transition to the new home office conditions was on quickly transferring work processes to digital tools for collaborative working and communication. With a weekly team meeting via the Software Free Conference, they are "making just as much progress as before in on-site meetings," says Torsten Klette. The necessary files are stored securely on the university server via the Micro Focus Filr file service and can still be accessed on the move. And thanks to internal coordination with Microsoft Teams, they have found a solution that supports the currently most important pivotal point of their project: transparent and clear coordination in the distribution of tasks.

As the project progresses, the findings will be tested on increasingly larger test stands, starting with the dimensions of a saucepan and ending with an industrial-sized specimen. "And we're right on schedule for that," writes Thomas Gubsch on behalf of the team when asked. And who knows, perhaps complete autoclaves will come out of Hagenwerder at some point, developed together with the Zittau/Görlitz University of Applied Sciences.

Text: Martin Kunack, Kristin Sprechert (Saxony5)