In power grids, exactly as much electrical power must be provided at any moment as is required by the consumer. The increasing proportion of photovoltaic and wind power plants with feed-in priority means that the so-called residual load, i.e. the difference between the power fed in from photovoltaic and wind power plants and the power required in the grid, is fluctuating more and more. This fluctuating residual load must be provided by conventional and flexibly controllable energy plants in order to be able to guarantee safety of supply. This is possible, among other things, through various storage solutions, which serve to increase the degree of flexibility of conventional energy plants and to compensate for the fluctuating residual load as quickly as possible and in an environmentally friendly manner.

Aim of our work is to provide a contribution to the flexibilisation of thermal energy systems. The provision of control energy should stabilize the power grid and grant safety of supply for the economy. Subject of the project is application oriented research for novel energy technologies.

With erection of the experimental plant THERESA in the Zittauer Power Plant Laboratory the experimental infrastructure was created, to experimentally analyse component and system properties through flexibilisation measures and to derive important knowledge for future operation of energy plants. THERESA reproduces a thermodynamic cycle with pre-heaters, steam generator, superheater, heat sink and thermal storage. That way heat source and heat sink are separated temporally. Maximum water-steam parameters are 160 bar and 350 °C, depending on the configuration.

Currently, we are carrying out experimental and methodical work aimed at the development of simulation-based dimensioning and integration methods. Results can also be transferred to the integration of storage systems in production plants and process engineering facilities.

Until availability of a final disposal site in deep geological formations the necessity exists in Germany to temporarilly store used nuclear fuel elements safely using transport and storage casks (TSC) at the power plant locations. This is done that way since 2005 and it must be assumed that it stays like that for more than 50 years. The problem with it is in this context that the designated TSC (CASTOR® V/19 and V/52) only have an operational license for 40 years at the moment. Furthermore, no reliable information is currently available on the long-term behavior of spent fuel. It should be added, that extrapolative modeling of radiochemical and thermomechanical material properties is hard to do for a conclusive assessment.

As a consequence, in the sense of public service for society there is a necessity but also a guarantee for the ability of the transport of used fuel elements to the final disposal site later, to evaluate and to possibly implement means for a non-invasive condition monitoring of TSC and their content.

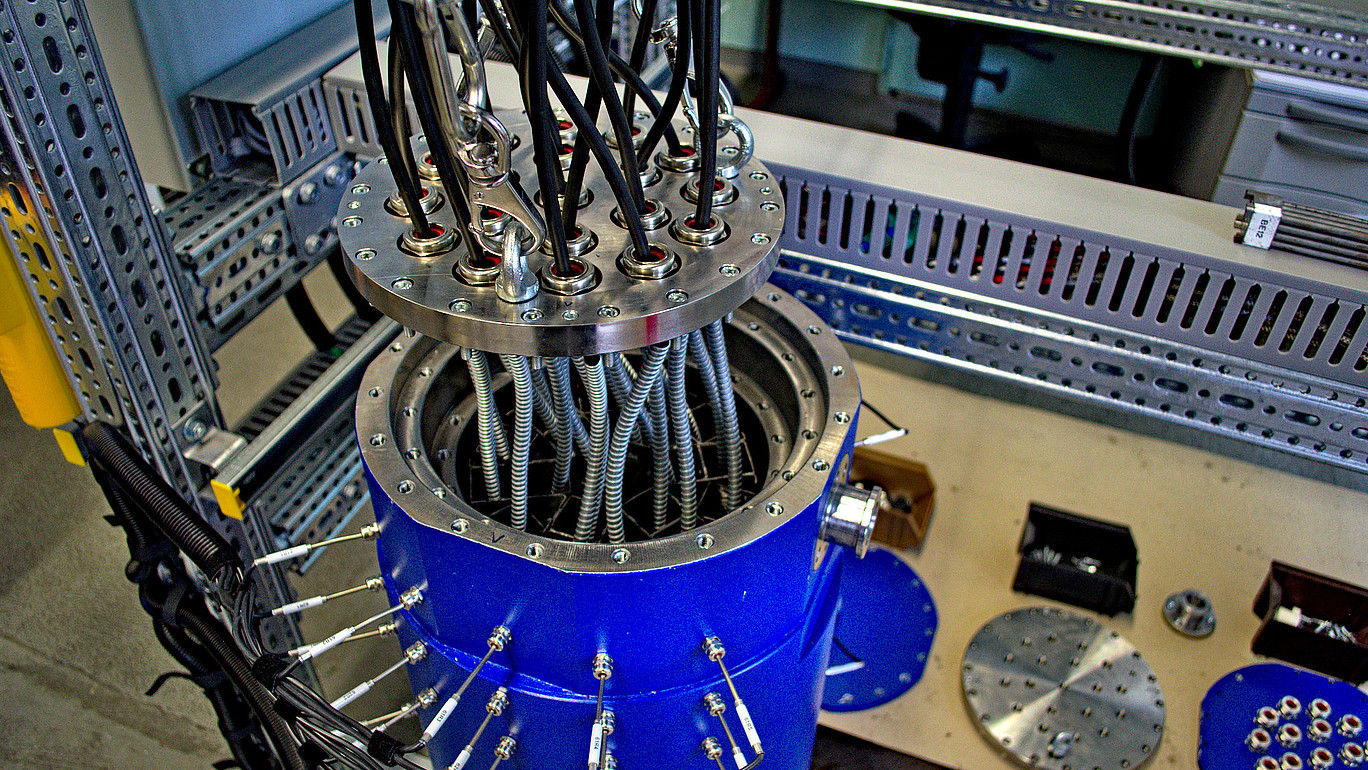

Extremely high activity of the stored content as well as the resulting massive structure of TSC (thick-walled spheroidal iron) restricting the spectrum of basically usable non-invasive condition monitoring methods hard. Aim of the joint project is to investigate means and methods for non-invasive condition monitoring of TSC respectively to allow for detection of changes of the cask content with its thermal and mechanical properties, without opening the TSC.

Goals of the project are experimental as well as simulative investigation and assessment of four measurement or operating principles: gamma emissions, thermografics, acustic emissions and vibration analysis.

Our task is to errect a suitable experimental infrastructure, carry out the investigation and to create together with project partner TU Dresden a procedural screening concept for condition monitoring of TSC.