The research project "Zittau Power Plant Laboratory" is a cross-faculty association of laboratory facilities for the investigation of power plant processes. The focus is on increasing energy efficiency and the use of renewable energies. At two locations in Zittau (Schliebenstraße 1 and Schwenninger Weg 1), three large-scale test facilities as well as several smaller test facilities are operated within the framework of research projects. In addition to research, teaching also benefits from this - in particular the course "Energy and Environmental Technology" and the new course "Automation and Mechatronics".

The large-scale project "Zittau Power Plant Laboratory" is funded by the European Regional Development Fund (ERDF) and the Free State of Saxony.

Dipl.-Ing. (FH) Torsten Klette

Fon: 03583 612-4732

Email: t.klette(at)hszg.de

Zittau, Theodor-Körner-Allee 8

buiding Z IV c, room C 1.14

Website of the Thermal Energy Storage Facility (THERESA)

The thermohydraulics laboratory of the Department of Nuclear Engineering/Soft Computing has test facilities that have been developed and used in a variety of different public and industrial projects. Modular system components allow the construction and experimental use of a wide variety of flow circuits for liquid media or multiphase systems. Heating and cooling components, complex partial geometries, sedimentation sections, free jets, screens and filters can be included. Adaptive image-based measuring devices are available as well as measuring technology for determining thermohydraulic and chemical parameters such as surface and media temperature, volume flow, differential pressure, conductivity and pH value.

An overview with technical data is provided in the test stand facility flyer (german/english)

Dipl.-Ing. Sören Alt

Fon: 03583 612-4879

Email: s.alt(at)hszg.de

Zittau, Lausitzer Weg 2

building VIIc, room 02

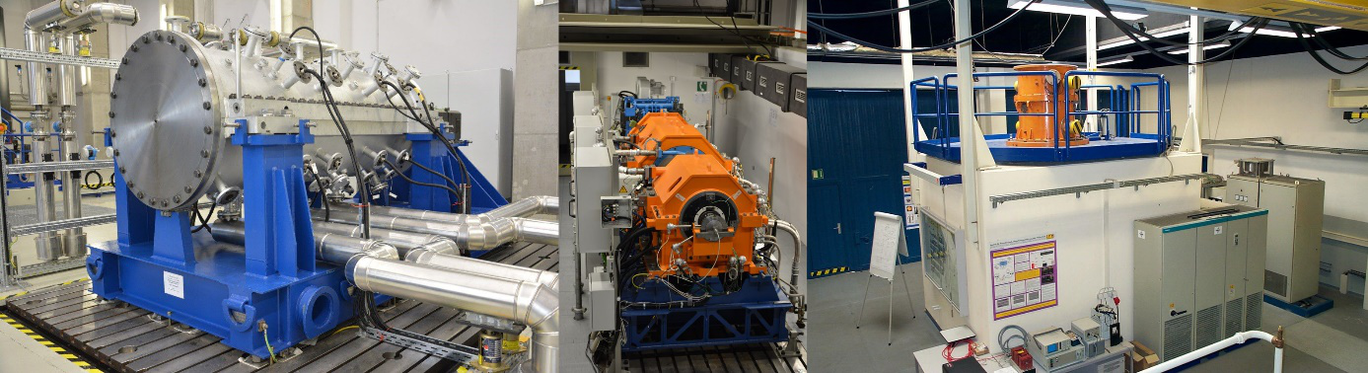

The Mechatronic Systems Department is equipped with three large-scale test facilities for experimental studies on the use of active magnetic bearings in turbomachines. The test facilities can be used to simulate operating conditions, such as those that prevail in pumps or turbines, and their effects on the magnetic bearing can be investigated experimentally. Depending on the research focus, the subject of the investigations is the stable function of the magnetic bearing in the simulated operating regime, the type and optimal mode of operation of the bearing cooling or the proof of the safe function of the catch bearings for various load scenarios. The test facilities are extensively instrumented for this purpose.

Dipl.-Ing. Ulrich-Steffen Altmann

Fon.: 03583 612-4743

Email: u.altmann(at)hszg.de

Zittau, Theodor-Körner-Allee 8

building Z IVc, room C1.06

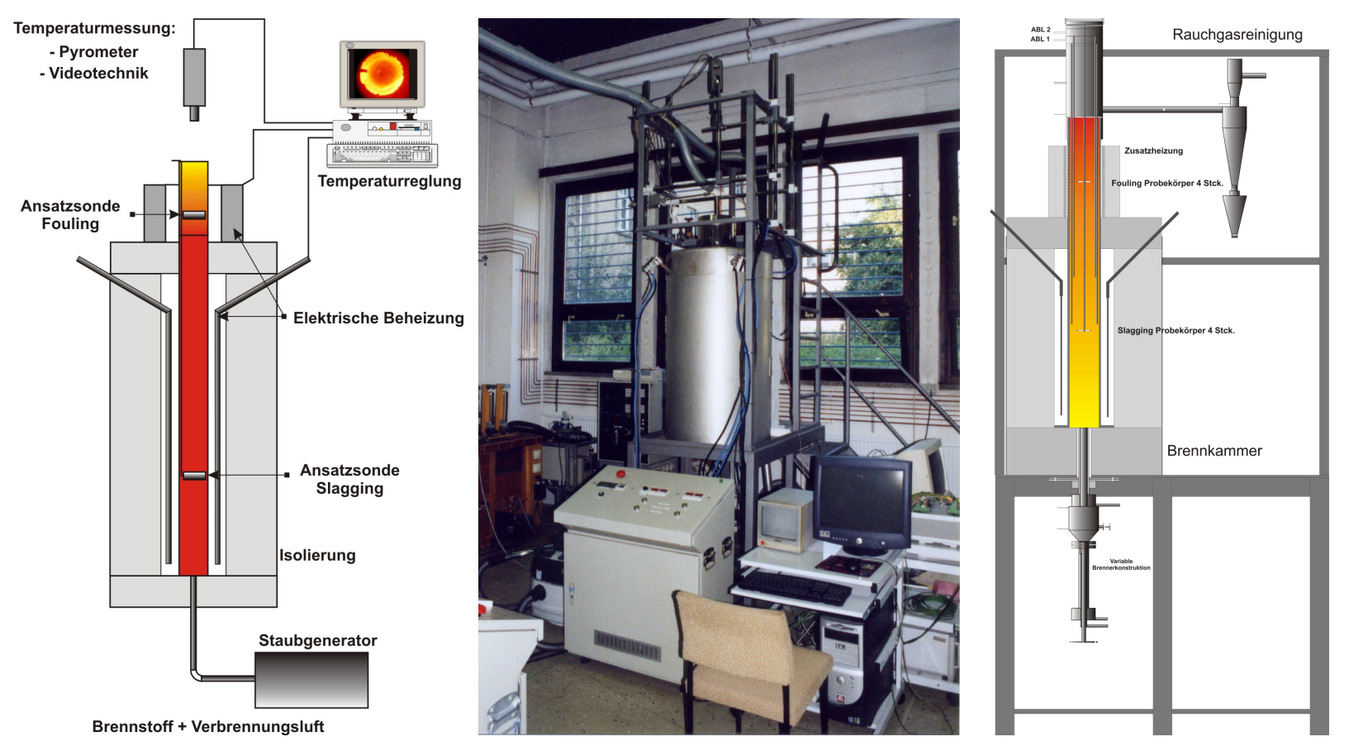

The laboratory for high-temperature technology of the Department of Power Plant, Steam Generator and Combustion Technology has micro combustion chambers (dust firing, up to 1500°C) and a model cyclone firing system. This is used to investigate the ignition and combustion behaviour, the slagging and fouling behaviour and the pollutant emissions of solid fuels, such as coal, biogenic materials and residues. The available measurement technology includes a fast data acquisition system for transient processes of the combustion kinetics, a flue gas analysis system, video monitoring of flame images and flame pyrometry. Optical methods for particle temperature determination and for the diagnosis of flame properties as well as conventional combustion chamber probes complete the measurement spectrum.

Dipl.-Ing. (FH) Christian Vanek

Fon: 03583 612-4739

Email: c.vanek(at)hszg.de

Zittau, Theodor-Körner-Allee 8

building Z IV c, room C 1.05

![[Translate to Englisch:] kollaborationsfähigeer Roboter (COBOT)](/fileadmin/_processed_/b/7/csm_Mensch_Roboter_Interaktion_163af4b5de.jpg)

The Laboratory for Human-Robot Interaction of the Department of Measurement Technology/Process Automation has two collaborative robots (COBOT) and a driverless transport system (AGV). Using various end effectors (e.g. two-finger grippers or vacuum grippers) and safety technology (e.g. laser scanners), robot systems are created for a wide range of issues from the regional economy and an optimal integration into a business environment is investigated. The focus is on relieving the burden on humans and on a fast, flexible, safe, modular and cost-effective solution for companies, especially for SMEs.

M. Eng. Christian Vogel

Fon: 03583 612-4984

Email: c.vogel(at)hszg.de

Zittau, Theodor-Körner-Allee 8

building Z IVc, room C1.14